AIR technology for a unique sound experience

High-end cables, hi-fi cables, audio cables, digital cables, phono cables - they have long since ceased to be a trivial factor in the hi-fi chain. It has been scientifically proven that cables have a major influence on the sound experience, especially when it comes to high-quality hi-fi and high-end systems.

Delivering music that is clear

and rich in emotions

Developed by our own in-house engineers, and used in combination with high-quality audio components, our AIR technology allows studio or live recordings to be reproduced in an authentic way and with minimum loss. The technology is now in its fifth generation.

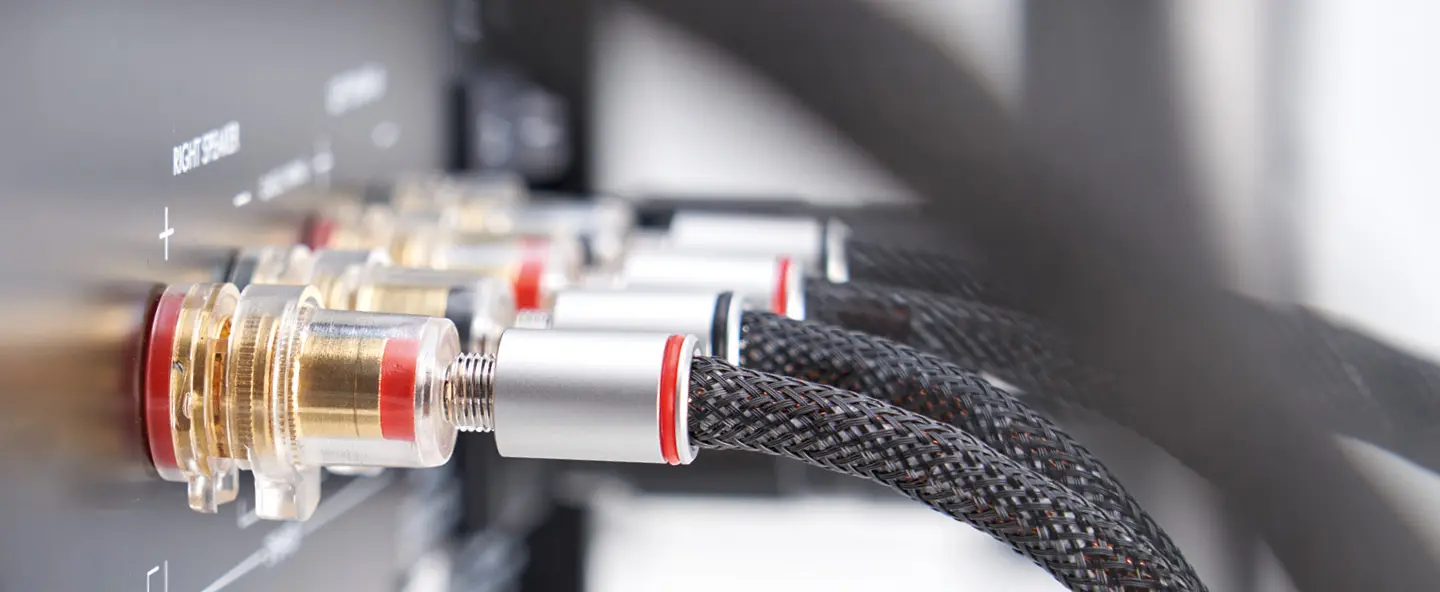

Our Referenz AIR cables transport audio signals between your high-end systems in an authentic way and with a minimum of loss.

How do we achieve this?

Resistance, inductance, capacitance, conductivity, material quality and skin effects all have a negative influence on the sound. The result is that audio signals are distorted during transmission. AIR technology diminishes such physical effects.

Emotional sound experiences

Enjoy music that precisely expresses the emotions of the artists at the time of recording. Our Referenz AIR cables transport vocals and instruments authentically, make emotions jump out at you and preserve the magic of the music, even when you’ve heard them a hundred times over.

To the AIR cables

Technical innovation

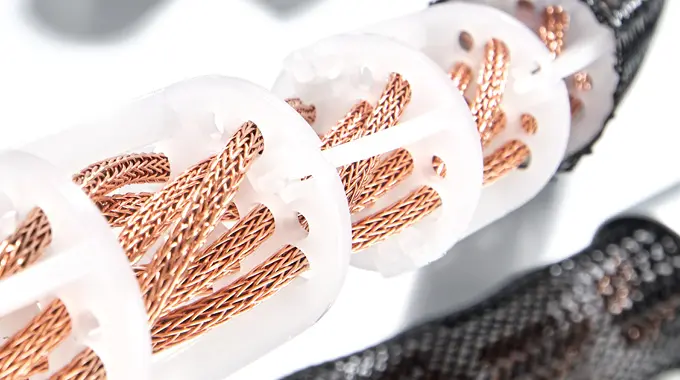

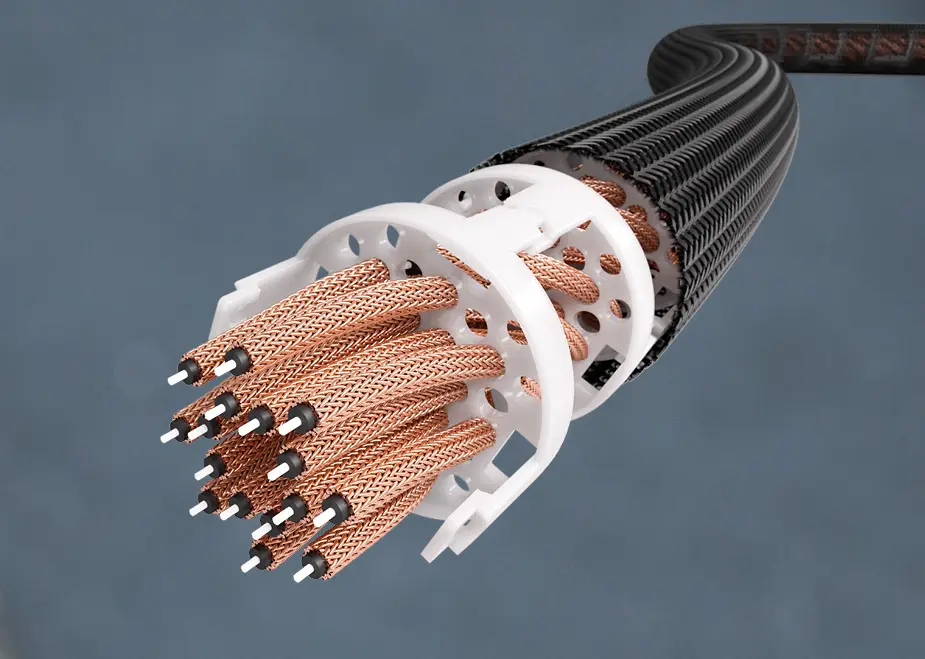

The unique Air Helix architecture of our Referenz AIR cables is at the heart of this exceptional technology. It is the key to transmitting unadulterated and low-loss audio signals between your source, your amplifier and your loudspeakers.

- Using air as a dielectric lowers capacitance to a minimum

- The Air Helix architecture enables the signal conductors to run freely suspended through the length of the cable

- Point-to-point Air Helix for end-to-end connections

- Multiple-nested multicore structures lower inductance

- Cross Link Super Speed waveguides bring homogeneous transport of electrical signals

- Excellent conductor materials: Copper and pure silver

- Easily attachable connectors with a long service life

- Securely pressure-grouted contacts (1.5 tonnes) for lower contact resistance

- PE network jacket without capacitance-enhancing materials

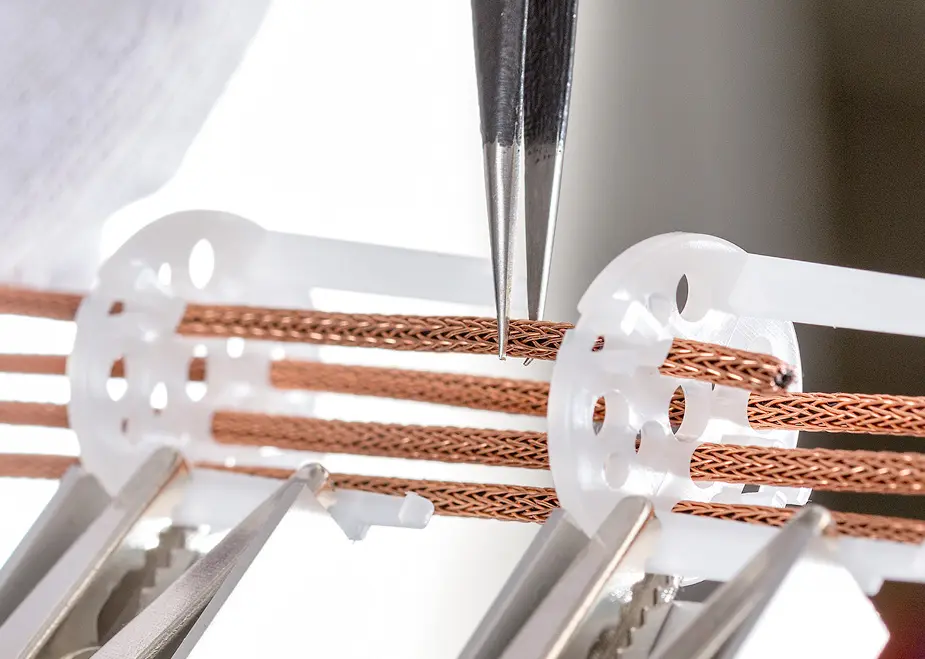

- Handmade in our manufacturing unit

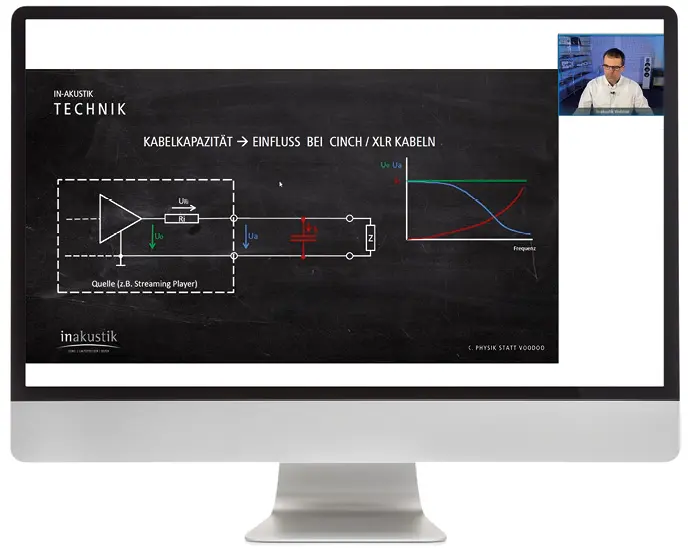

Using air as a dielectric lowers capacitance to a minimum

The insulation between the conductors (also known as the “dielectric”) is of key importance for the quality of the sound. Signal transport is impacted by the insulating material, the distance between the conductors and the surface of the conductors.

In comparison with other insulators, using air as a dielectric leads to no increase in capacitance and creates no dielectric losses.

Sound signals are not impeded or altered during transport,

a vital advantage when it comes to audio playback.

Our 5th generation Referenz AIR cables use solely air as a dielectric.

In the video, we use an experiment to demonstrate the influence of different insulation materials and distances.

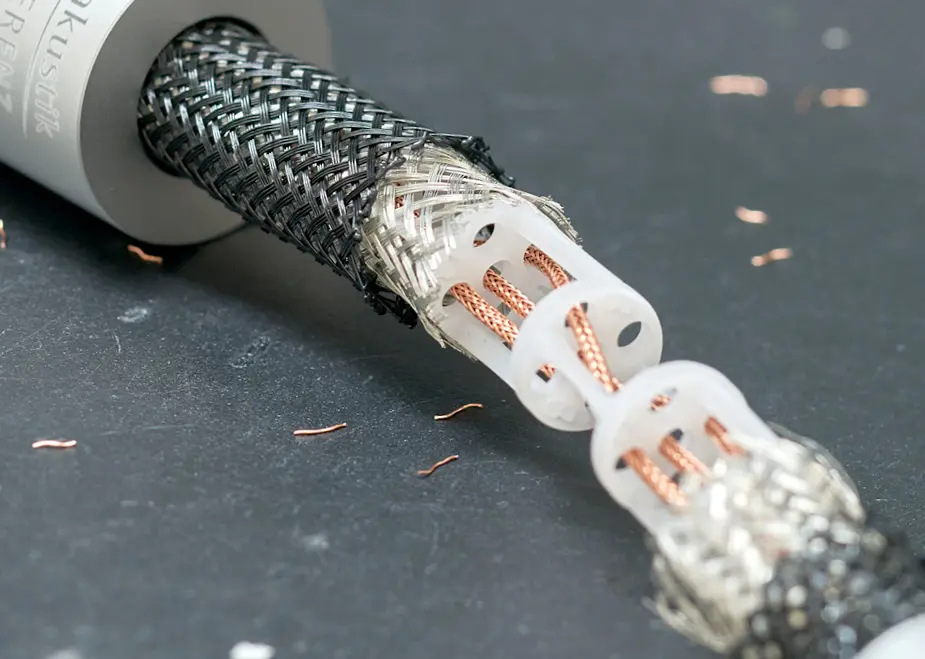

Thanks to the Air Helix architecture, the conductors run freely suspended through the cable

The Air Helix architecture permits signal conductors to be insulated to practically 100% by air. Special clips were developed to provide the supporting framework. Positioned at defined intervals inside the cables, these clips keep the helically-arranged conductors apart. Cable flexibility is assured by means of two struts that ensure the clips remain together but also at a precise distance from each other. This architecture is unique, bringing low capacitance and minimum dielectric losses – a true milestone in the search for open and unadulterated sound.

Point-to-point Air Helix for end-to-end connections

A new feature in the 5th generation of in-akustik’s Air Helix architecture is the point-to-point connection. Specially designed transitions are available for each type of cable and connector. Across the complete length of the cable – point-to-point AIR Helix. It may sound trivial at first, but the results are impressive. Sound signals are transported with minimized losses, right through to the final centimeters. The sound is more detailed and dynamic than even before.

Multiple-nested multicore structures lower inductance

Inductance is critical to the capacitance of a loudspeaker cable, causing resistance to the signal flow, rising with the frequency. Current flow through a cable creates magnetic fields. Depending on how closely together cables are arranged, and on the direction in which the current is flowing, cables have an influence on each other. Their magnetic fields can be neutralized or increased. In our multicore architecture, we deliberately exploit stray magnetic fields. By cleverly arranging the conductors in the multiply nested multicore structures, overlapping magnetic field areas are created that significantly reduce inductance. This allows the entire frequency spectrum, including high frequencies and dynamic impulse sequences, to be transported in an unimpeded way and with no delays. The music seems more exquisitely detailed, and the sound gains in fine dynamism. All details are kept distinct yet harmonious at the same time.

Cross Link Super Speed waveguides bring homogeneous transport of electrical signals

The Cross Link Super Speed waveguide avoids so-called “skin effects” caused by eddy currents in the conductor that occur with increasing frequencies and high energetic impulses. It has a polyethylene core and a ring-shaped structure, with a usable cross-section that remains the same for all frequencies and in all situations. Thanks to the braided structure, the waveguide is able to precisely transport even extreme current peaks. A lacquer coating around each wire prevents eddy currents within the conductor and protects the wires against oxidation. All this results in a conductor that delivers a balanced sound consisting of vibrant and never overemphasized timbres, even in complex musical passages and at high volume levels.

Excellent conductor materials: pure copper or silver

The conductor material is a crucial factor for the transmission of sound signals. Any impurity in the conductor material impedes the flow of current, diminishes the conductivity and increases background noise, also known as “shot noise”. We therefore use only pure oxygen-free copper (OFC) or pure silver in our Referenz AIR cables. Both materials have an excellent conductivity value.

Copper conductor: When using copper, we ensure that only carefully selected batches of pure copper are processed. We take great pains to measure the quality of the copper before it is sent to the mill for drawing to the required cross-section over the course of a multi-stage process.

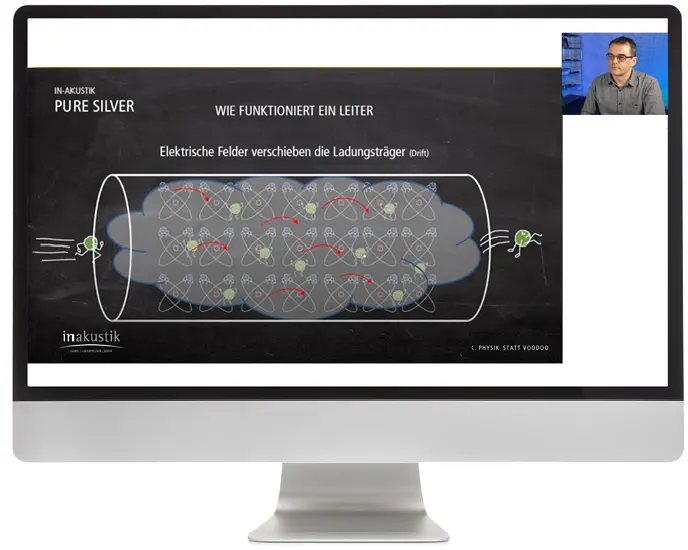

Pure silver conductors: A material’s electrical conductivity depends on the number of free electrons and their drift speed. Pure silver is regarded as the best conductor, delivering more detail across all frequency ranges. The charismatic sound of pure silver is primarily due to its high drift speed. Pure silver cables shouldn’t be confused with silver-plated cables. Silver-plated cables are said to lend a metallic and aggressive character to the sound, something pure silver cables never do.

Rhodium-coated connectors prolong cable lifetimes

Even the best cable deteriorates massively in quality when insufficient attention is paid to the connection technology. Pure copper is not suitable here due to the softness of the material. At in-akustik, we therefore use tellurium copper, an alloy of copper and tellurium. This alloy is a harder metal. Its great advantage is that the conductivity remains at a high level, much superior to that of brass connectors. The additional coating with rhodium ensures robust connectors with high longevity and high resistance to corrosion. The precious metal is capable of withstanding numerous connection cycles, continuing to display good contact characteristics even after frequent reconfigurations and experimentation. Conductivity also remains at a high, stable level. These are important advantages, particularly compared to contact enhancement using gold, a softer material that rubs off more quickly.

Securely pressure-grouted contacts (1.5 tonnes) for lower contact resistance

Soldering is normally regarded as a robust and reliable technique for use in connection technology. However, it has disadvantages when used for audio cables, such as less-conductive solder in the signal path and the emergence of low thermoelectric emfs. Both factors diminish audio signal flow, even if the effect is minimal. The contact elements on the RCA and BFA plugs and lugs (spades) belonging to our Referenz AIR cable range are pressure-grouted together with the conductor material using a special tool that exerts a force of 1.5 tonnes. This ensures a stable and reliable connection between the connector and the Referenz AIR cable without needing ferrules or an additional material such as solder. Contact resistance and other negative effects are avoided.

Polyethylene network jacket without sub-coating

There is a huge number of cables on the market, most with a PVC sheath surrounded by a textile or plastic braid. This sheath is meant to protect the cable from mechanical damage. In the hi-fi area, however, it is unsuitable because (depending on the cable type) the jacket may act as part of the dielectric, negatively impacting capacitance and causing dielectric losses. At in-akustik, we deliberately don’t use a PVC sheath in order to avoid capacitance and any consequent dielectric losses. The sheaths for Referenz AIR cables are made of polyethylene monofilaments. These hold the conductors tightly together, reduce microvibrations and allow extreme dynamic peaks to be processed in an unadulterated fashion.

Hand-crafted, custom-made cables

Every single cable in our Exzellenz and Referenz series is carefully assembled by hand in Ballrechten-Dottingen. Our in-house expertise and the skills of our workforce enable us to manufacture technically intricate cables and customize them in line with the wishes of our customers. Apart from the finest of materials, our most importance resource is the manual dexterity of our cable assemblers. In assembling our outstanding cables, our team needs to demonstrate meticulousness, composure, enthusiasm and dedication.

Webinar: Busting myths about high-end hi-fi cables

HiFi cables are available from just a few euros up to several thousand. How does a simple speaker cable differ from a high-end cable? Electrical engineers often regard the whole topic as “voodoo”. Rightly so?

- How the cable affects the sound of your system

- High-end cables: myth or real physics?

- What you should never do if you want to get the most out of your system

Webinar: HiFi cable with silver conductors

Speaker cables with copper conductors, silver-plated audio cables or hi-fi cables with pure silver conductors. What are the differences? Even a pure silver cable can’t work miracles, but it permits maximization of the possibilities. How much should this be worth to us?

- Myth: Silver cables sound "cold"

- If silver is such a good conductor, why isn't it always used?

- Silver in the electrical industry vs. silver in the hi-fi sector