€1,849.00*

Breathtaking sound thanks to air insulation - we have already created many innovative designs on the way to perfect insulation, such as DUO-PE insulation or PETS (PE Tube Support). The Referenz NF-2405 cable is another true milestone and an absolute world first in the cable sector.

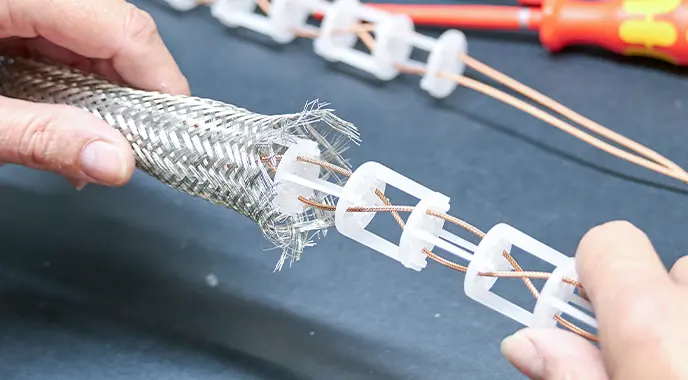

Normally, the conductors are kept at a distance from each other by more or less high-quality filling and insulation materials. With the NF-2405, however, the conductors run through a series of clips connected in series, which form the inner framework and give the NF-2405 exceptional flexibility for high-end cables.

The NF-2405 is manufactured entirely in Germany, like all speaker and audio cables in the Referenz series. The clips are assembled by hand with meticulous care in the company's own factory and then the Cross Link super-speed waveguide is threaded in. The resulting Air Helix is then also shielded by hand and fitted with a PE network jacket before the finished cable is assembled with the XLR 180° connectors developed in-house.

New XLR 180° plug: It is only possible to insert XLR connectors in one direction. This can be annoying as the position of the XLR sockets in devices varies. In order for the cable to fit, it must sometimes be twisted by force. This puts a strain on cables, plugs and device sockets and sometimes simply looks a mess. The new XLR 180° plugs developed in-house can be rotated by +/- 45 degrees, i.e., up to a total of +/- 90 degrees from connector to connector. The finishing touch for perfect cabling.

| Application: | High-end audio cable |

|---|---|

| Cable diameter: | 25 mm |

| Conductor design: | Cross Link Super Speed waveguide |

| Conductor material: | High-purity OFC copper |

| Conformity: | CE, REACH, RoHS |

| Connector assembly: | Soldering |

| Connector housing: | Solid metal |

| Contact enhancement: | Rhodium-coated |

| Contact material: | Tellurium copper |

| Customized assembly: | On request |

| Design: | Double symmetrical |

| Dielectric: | Air |

| Jacket: | PE network jacket |

| Length: | 1 m, 1.5 m, 2 m |

| Shielding: | Dense copper braid, tin-plated (oxidation protection) |

| Product group: | Home HiFi |

| Product category: | Analog interconnects |

| Quality: | Referenz |

| Technology: | AIR Helix Point-to-Point Double mono |

| Connector: | 2 x XLR (f) > 2 x XLR (m) |

| Connector highlight: | XLR 180 | +/- 45° rotatable |

| Made in Germany: | Yes |

| Free trial listening: | Yes |

- Stereo set NF-2405 XLR 180°

- Quality certificate

- Warranty card

- CD "Der Anlagenberater"

- Universal user manual

- Company profile

Breathtaking sound thanks to air insulation - we have already created many innovative designs on the way to perfect insulation, such as DUO-PE insulation or PETS (PE Tube Support). The Referenz NF-2405 cable is another true milestone and an absolute world first in the cable sector.

Normally, the conductors are kept at a distance from each other by more or less high-quality filling and insulation materials. With the NF-2405, however, the conductors run through a series of clips connected in series, which form the inner framework and give the NF-2405 exceptional flexibility for high-end cables.

The NF-2405 is manufactured entirely in Germany, like all speaker and audio cables in the Referenz series. The clips are assembled by hand with meticulous care in the company's own factory and then the Cross Link super-speed waveguide is threaded in. The resulting Air Helix is then also shielded by hand and fitted with a PE network jacket before the finished cable is assembled with the XLR 180° connectors developed in-house.

New XLR 180° plug: It is only possible to insert XLR connectors in one direction. This can be annoying as the position of the XLR sockets in devices varies. In order for the cable to fit, it must sometimes be twisted by force. This puts a strain on cables, plugs and device sockets and sometimes simply looks a mess. The new XLR 180° plugs developed in-house can be rotated by +/- 45 degrees, i.e., up to a total of +/- 90 degrees from connector to connector. The finishing touch for perfect cabling.

Breathtaking sound thanks to air insulation - we have already created many innovative designs on the way to perfect insulation, such as DUO-PE insulation or PETS (PE Tube Support). The Referenz NF-2405 cable is another true milestone and an absolute world first in the cable sector.

Normally, the conductors are kept at a distance from each other by more or less high-quality filling and insulation materials. With the NF-2405, however, the conductors run through a series of clips connected in series, which form the inner framework and give the NF-2405 exceptional flexibility for high-end cables.

The NF-2405 is manufactured entirely in Germany, like all speaker and audio cables in the Referenz series. The clips are assembled by hand with meticulous care in the company's own factory and then the Cross Link super-speed waveguide is threaded in. After this, the resulting air helix is also shielded by hand and given a PE network jacket before the finished cable is assembled using the RCA plugs we developed ourselves.

New RCA SL connector: Soldering is a reliable and well-established joining technique, but it has its drawbacks. Disadvantages include the presence of poorly conducting solder in the signal path and the emergence of low thermoelectric emfs. With the SL RCA Plug developed in-house, the connections from the signal conductor to the contact elements are precisely pressure-grouted together using a force of 1.5 tonnes. A further seemingly tiny improvement that brings great rewards in terms of audio performance.

Cable capacitance plays a decisive role, especially for audio cable connections between individual devices. As the signal sources are very weak and react sensitively to high cable capacitance, audio cables are virtually predestined for air insulation using air helix technology.

New XLR 180° plug: It is only possible to insert XLR connectors in one direction. This can be annoying as the position of the XLR sockets in devices varies. In order for the cable to fit, it must sometimes be twisted by force. This puts a strain on cables, plugs and device sockets and sometimes simply looks a mess. The newly developed XLR 180° plugs can each be rotated by +/- 45 degrees, i.e. +/- 90 degrees in total. The finishing touch for perfect cabling.

€1,849.00*

€1,749.00*

€1,299.00*

Login

Thanks to the Air Helix design, the conductors run freely suspended through the length of the cable.

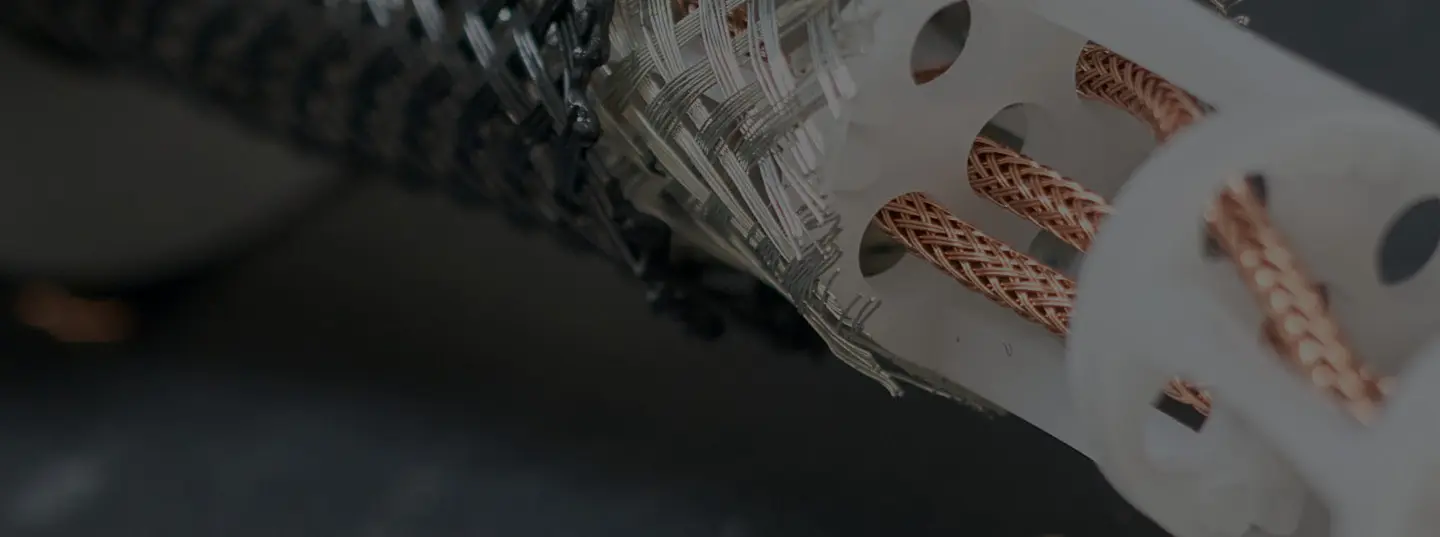

The Air Helix architecture permits signal conductors to be insulated to practically 100% by air. Special clips were developed to provide the supporting framework. Positioned at defined intervals inside the cables, these clips keep the helically-arranged conductors apart. Cable flexibility is assured by means of two struts that ensure the clips remain together but also at a precise distance from each other. This architecture is unique, bringing low capacitance and minimum dielectric losses – a true milestone in the search for open and unadulterated sound.

Our physical approach: Minimize losses for true-to-original playback.

Our Referenz AIR cables transport audio signals between source, amplifier and speaker in an authentic way and with a minimum of loss. You can enjoy music that precisely expresses the emotions of the artists at the time of recording – sensual, subtle, light-hearted or orchestral right through to full-blooded and rocking. Vocals and instruments are delivered in unadulterated form. Everything remains vibrant and full of emotive energy. Favorite tracks and pieces continue to trigger strong feelings even when you’ve heard them a hundred time over.

To the point

AIR Helix

The Air Helix architecture enables the signal conductors to run freely suspended through the length of the cable and permits signal conductors to be insulated to practically 100% by air.

The dielectric

Using air as a dielectric lowers capacitance to a minimum. In comparison with other insulators, using air as a dielectric leads to no increase in capacitance and creates no dielectric losses.

Multicore structure

By cleverly arranging the conductors in the multiply nested multicore structures, overlapping magnetic field areas are created that significantly reduce inductance.

The conductors

The Cross Link Super Speed waveguide avoids so-called skin effects and delivers a balanced sound, even with complex music passages and high volume levels.

XLR 180°

The Referenz XLR 180° connectors developed by us can be rotated by +/- 45 degrees and can therefore be optimally adapted to individual socket alignments. Cables and sockets are less stressed.

Point-to-point Air Helix for end-to-end connections

A new feature in the 5th generation of in-akustik’s Air Helix architecture is the point-to-point connection. Specially designed transitions are available for each type of cable and connector. Across the complete length of the cable – point-to-point AIR Helix. It may sound trivial at first, but the results are impressive. Sound signals are transported with minimized losses, right through to the final centimeters. The sound is more detailed and dynamic than even before.

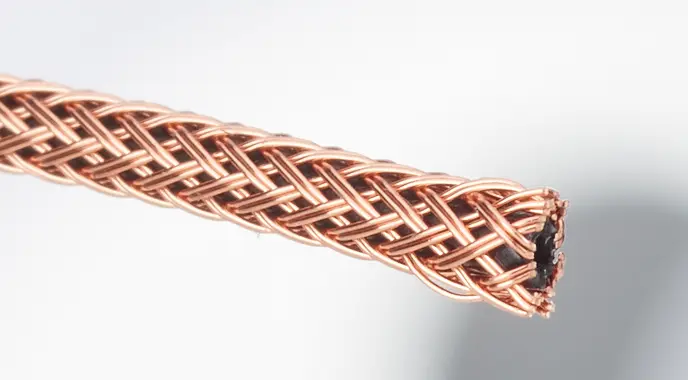

The conductor structure

The Cross Link Super Speed waveguide avoids skin effects caused by eddy currents in the conductor. Thanks to the braided structure, the waveguide is able to precisely transport even extreme current peaks. A lacquer coating around each wire prevents eddy currents within the conductor and protects against oxidation. All this results in a conductor that delivers a balanced sound consisting of vibrant and never overemphasized timbres, even in complex musical passages and at high volume levels.

The conductor material

The conductor material is a crucial factor for the transmission of sound signals. Any contamination worsens the conductance and increases the background noise. We only use pure, oxygen-free copper in our AIR cables. We ensure that only carefully selected batches of pure copper are processed. We take great pains to measure the quality of the copper before it is sent to the mill for drawing to the required cross-section over the course of a multi-stage process.

The shielding

EMC interference, from sources such as mobile phone and WiFi networks, is constantly increasing. This interference impairs the sensitive audio signal. Interference occurs when signals of different frequencies overlap. This can result in unwanted distortions that have nothing to do with the original signal. Dense shielding is therefore essential to protect the extremely sensitive music signals from this interference so that even the finest details are preserved.

Cable manufacturing unit

The beating heart of in-akustik is our manufactory. This is where our success story is rooted – permeated by a congenial working atmosphere, a love of music and a passion for detail. At in-akustik, we believe musical enjoyment stems from a listening experience that remains as close as possible to the original recording and the artist’s interpretation of the piece. That’s why we boast a committed workforce that combines curiosity with a keen sense of precision. With a fascination for music and things that are really special – like the development of our complex AIR cables.

Handmade

Each cable is handcrafted with the utmost care. Our extensive know-how and the qualifications of our team enable us to manufacture the complex cables in a customized manner. Apart from the finest of materials, our most important resource is the manual dexterity of our cable assemblers. In assembling our outstanding cables, they demonstrate meticulousness, composure and dedication.

Rigorous quality control

We manufacture in accordance with the highest standards. Rigorous quality control is carried out before, during and subsequent to assembly. We verify the tolerances of ever individual component. At every stage of manufacturing, we check the configuration and electrics for short-circuits. We also conduct functional and mechanical testing. No product leaves our manufacturing unit without a final quality check.

Did you know...

...that our NF-2405 AIR (2 x 1.5 m) is made up of 195 individual components? The copper wire used is 1,109 m long, and the PE monofilament is 388 m long. Containing 296 drill holes, the Air Helix design of this cable type demands great dexterity on the part of the assemblers when they’re threading through the conductors.

XLR 180° connector

Conventional XLR connectors are designed for fixed positioning, which often forces the cable to twist. This load causes increased mechanical stress. In contrast, our proprietary XLR 180° connector offers a unique and adjustable alignment that allows the connector to be rotated within a range of +/- 90 degrees. This flexibility not only reduces the mechanical stress on the cable, it also enables optimum alignment of the cable in relation to the device sockets, which are often arranged differently from device to device.

Rhodium-coated

The best cable requires optimum connection technology. We use tellurium copper, a harder metal alloy that maintains the high conductivity value. Much superior to that of brass connectors. The rhodium coating ensures long-lasting contact and corrosion resistance. The stable conductivity is even maintained with frequent conversions. This is better than gold contacts, which wear out quicker.

PE network jacket

Most cables have a PVC sheath surrounded by a textile or plastic braid. This sheath is meant to protect the cable from mechanical damage. At in-akustik, we deliberately don’t use a PVC sheath in order to avoid capacitance and any consequent dielectric losses. The sheaths for AIR cables are made of polyethylene monofilaments. These hold the conductors tightly together, reduce microvibrations and allow extreme dynamic peaks to be processed in an unadulterated fashion.

Test listening at home now

Are you curious to know whether the AIR cables keep the finest details precisely and harmoniously on your system? Test our AIR cables or an audio component from our partner companies Primare and Audiovector in your home for 14 days with no strings attached!

Book a listening sessionOr directly to the nearest dealer!

We work with a network of authorized dealers and distributors throughout the world. Arrange a listening appointment now.

Find a in-akustik partner