Cable manufacturing at

the heart of in-akustik

The beating heart of in-akustik, its in-house cable plant, is located in Ballrechten-Dottingen, Germany. This is where our success story is rooted – permeated by a congenial working atmosphere, a love of music and a passion for detail.

Innovative development and manufacturing of cables and electronic components

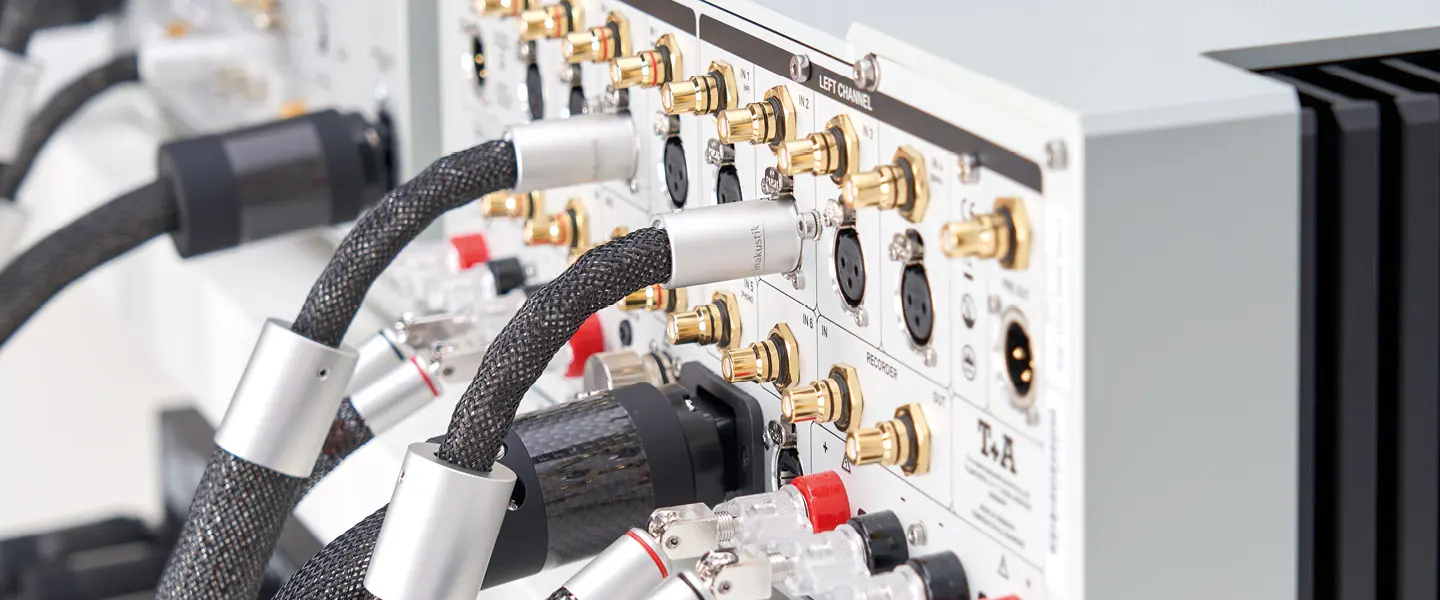

We specialize in developing cables that enable practically loss-free signal transport between playback device, amplifier and speakers.

Developing a new cable is a slow and arduous process.

The various design and construction phases between conception and production are accompanied by frequent tests, rejections, corrections, variations and checks.

Cables and connectors are highly sensitive objects.

Keeping the typical physical phenomena that occur during transmission of signals in check requires technical skills and the very best materials.

We work day in and day out on further refinements.

Utilizing our AIR technology, developed in-house, we have created cables that transport audio signals with scarcely any loss over the entire frequency range.

The sound spectrum is enhanced in terms of both clarity and precision.

The Power-Station AC-4500 is our latest innovation.

Developed entirely in-house, like our AIR cables this power filter is also manufactured at our own production facility.

High-quality materials

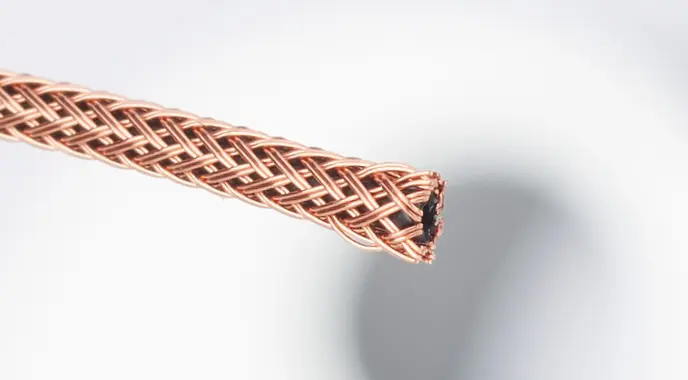

Crucial to the quality of cables are their design, their shielding and the materials we use. Alongside cable architecture, we place a special emphasis on high-quality materials. We use only the purest and most conductive copper for our copper cables. Cast to a thickness of around 10 mm, the coils of copper wire are subjected to stringent purity tests. At a German mill, the copper wire is then drawn in several stages until the required diameter is reached, followed by further processed at a cable plant in Germany. Finally, the cable is refined and assembled in our in-house manufacturing unit. We use only the best high-purity oxygen-free copper for the reference AIR cables.

Customized cables

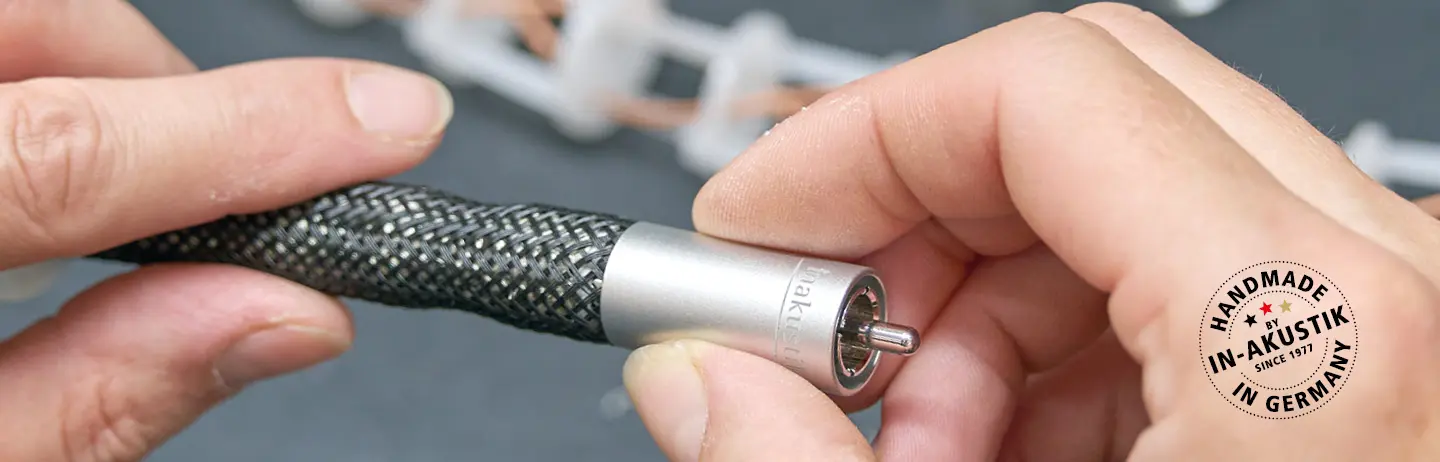

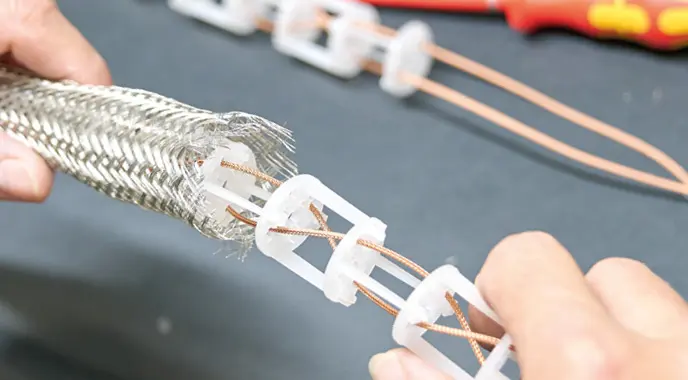

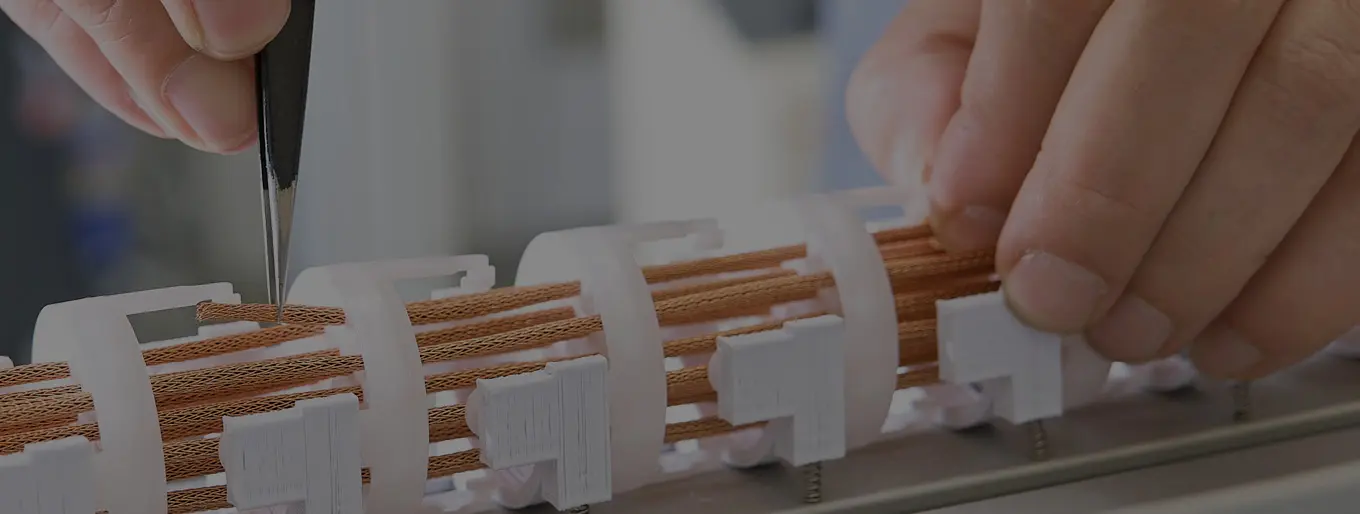

Every single cable in our Exzellenz and Referenz series is carefully assembled by hand in Ballrechten-Dottingen.

Our in-house expertise and the skills of our workforce enable us to manufacture technically intricate cables and customize them in line with the wishes of our customers..

Apart from the finest of materials, our most importance resource is the manual dexterity of our cable assemblers.

In assembling our outstanding cables, our team demonstrates meticulousness, composure, enthusiasm and dedication.

Did you know that ...

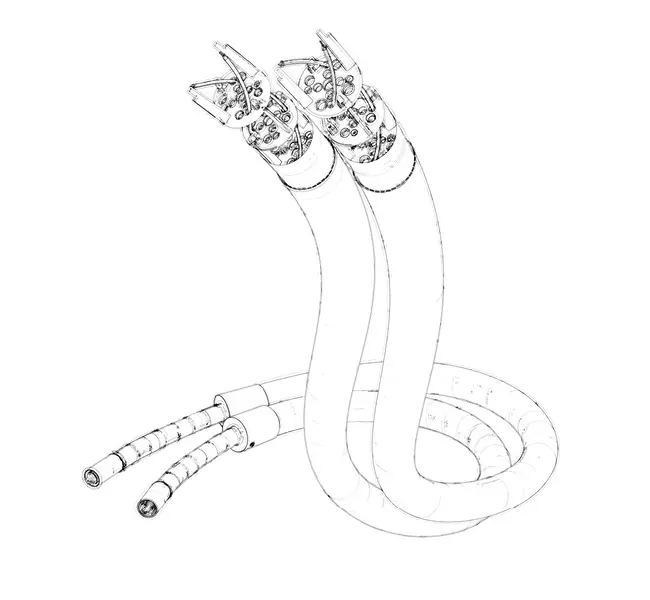

our LS-4005 AIR Referenz cable (2 x 3.0 m) is made up of 354 individual components? The copper wire used has a length of 4,601 meters and the PE monofilament is 1,723 meters long. The Air Helix structure used in this cable type has 1,904 holes, demanding great skill when threading the conductors.

Rigorous quality control

We manufacture in accordance with the highest standards. Rigorous quality control is carried out before, during and subsequent to assembly. We verify the tolerances of ever individual component. At every stage of manufacturing, we check the configuration and electrics for short-circuits. We also conduct functional and mechanical testing. No product leaves our in-house manufacturing unit without a final quality check.

Logistics

We operate an ERP-driven logistics center that ensures optimum availability and smooth material flows. Our cable and accessory products are stored and prepared for dispatch in our high-bay warehouse, boasting 3,000 storage locations across 1,350 m² of warehouse space.

AIR technology

The technology sets new standards. Audio signals are impacted by a variety of factors: resistance, inductance, capacitance, insulation and skin effects all have a negative influence on the sound. As a result, the fragile signals are distorted during transmission. Our specially developed AIR technology reduces any resulting losses to a minimum. The 5th generation of this technology is now available.

Cable solutions for industry

On request, we also accept orders for the development and production of sophisticated cable solutions for other industries.

HiFi & Enjoyment Day at in-akustik

Many thanks to all visitors to the first HiFi, Music and Enjoyment Day at in-akustik. It was a pleasure to meet with you and talk about our shared passion – music and its audiophile reproduction. The video on the right contains a few impressions and statements from our visitors.

If you would like to attend the next event, we will be happy to keep you up to date via our newsletter. You can register at any time in the footer at the bottom of the page. We look forward to seeing you.