€35,499.00*

AIR technology is a milestone in our more than 46-year company history and is causing a sensation in the hi-fi industry worldwide. The approach itself sounds relatively banal: The physically induced losses must be minimized in order to transmit the original music signal as authentically and neutrally as possible. And, thanks to the AIR technology, loss-free transmission is closer than ever before. It leads to a significantly better reproduction, which is not only subjectively audible, but also objectively measurable.

The insulation (or dielectric) of the AIR cables is practically perfect thanks to the air insulation, and hardly affects the sound at all. The structure, dimensions and arrangement of the conductors are optimized, and approach the limits of what is physically possible. Adding another highlight to this perfect audiophile foundation, we then focused on the conductor material of the cables. Copper in the appropriate purity is already a very good conductor. A superconductor, where electrical resistance is zero, would be perfect, of course.

Unfortunately, superconducting materials require temperatures of at least -70 degrees. Under realistic operating conditions, the best conducting material we have is currently silver. At 61.35 S/m (Siemens pro Meter), its conductivity is approximately six percent superior to that of copper. However, this precious metal is about 100 times more expensive.

Below you can learn more about the outstanding technical features of this cable, the innovations in the 5th generation and the physical principles used in the AIR technology.

Click here and discover the exciting details| Application: | High-end speaker cable |

|---|---|

| Cable diameter: | 40 mm |

| Conductor cross-section: | 2 x 9.6 mm² (16 x 1.2 mm²) |

| Conductor design: | Cross Link Super Speed waveguide |

| Conductor material: | High-purity silver |

| Conformity: | CE, REACH, RoHS |

| Connection type: | SBW, SW |

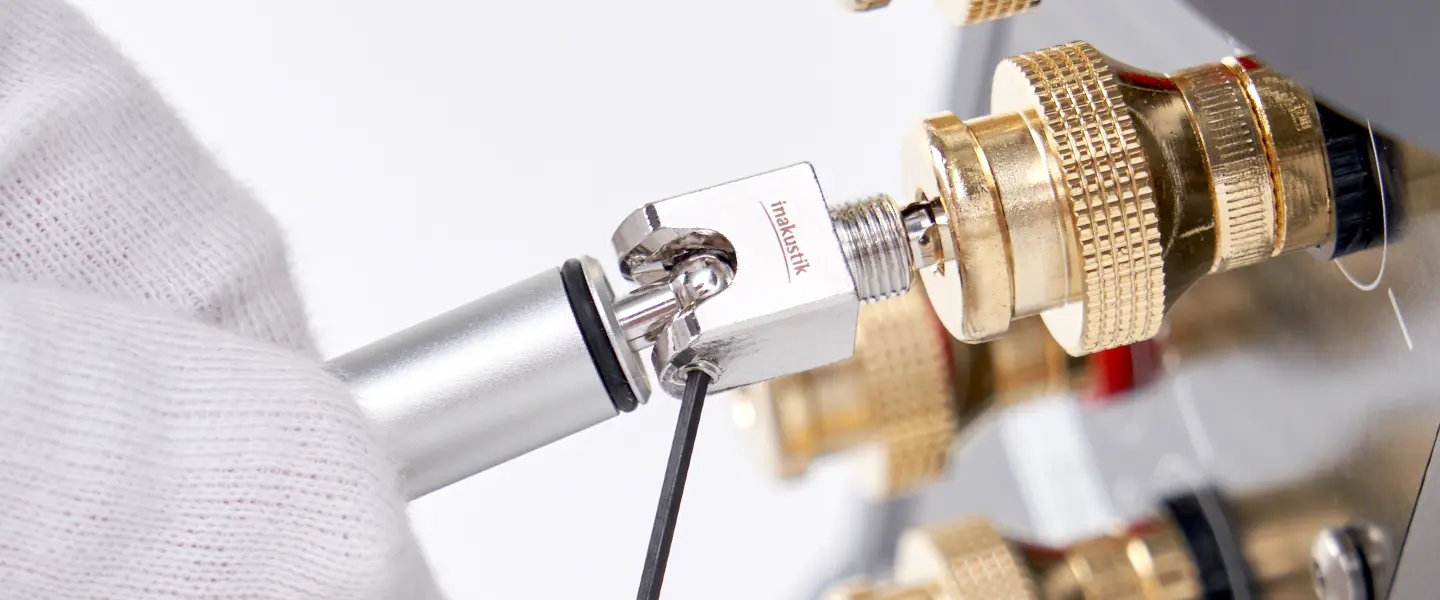

| Connector assembly: | Pressure-grouted contacts (1.5 tonnes) |

| Connector housing: | Solid metal |

| Contact enhancement: | Rhodium-coated |

| Contact material: | Beryllium Copper (BFA Banana), Tellurium copper (cable lug) |

| Customized assembly: | On request |

| Design: | 16-fold double layer multicore |

| Dielectric: | Air |

| Jacket: | PE network jacket |

| Length: | 2 x 3 m |

| Product group: | Loudspeaker cables |

| Product category: | Referenz speaker cables |

| Quality: | Referenz |

| Technology: | AIR Helix Point-to-Point Multicore |

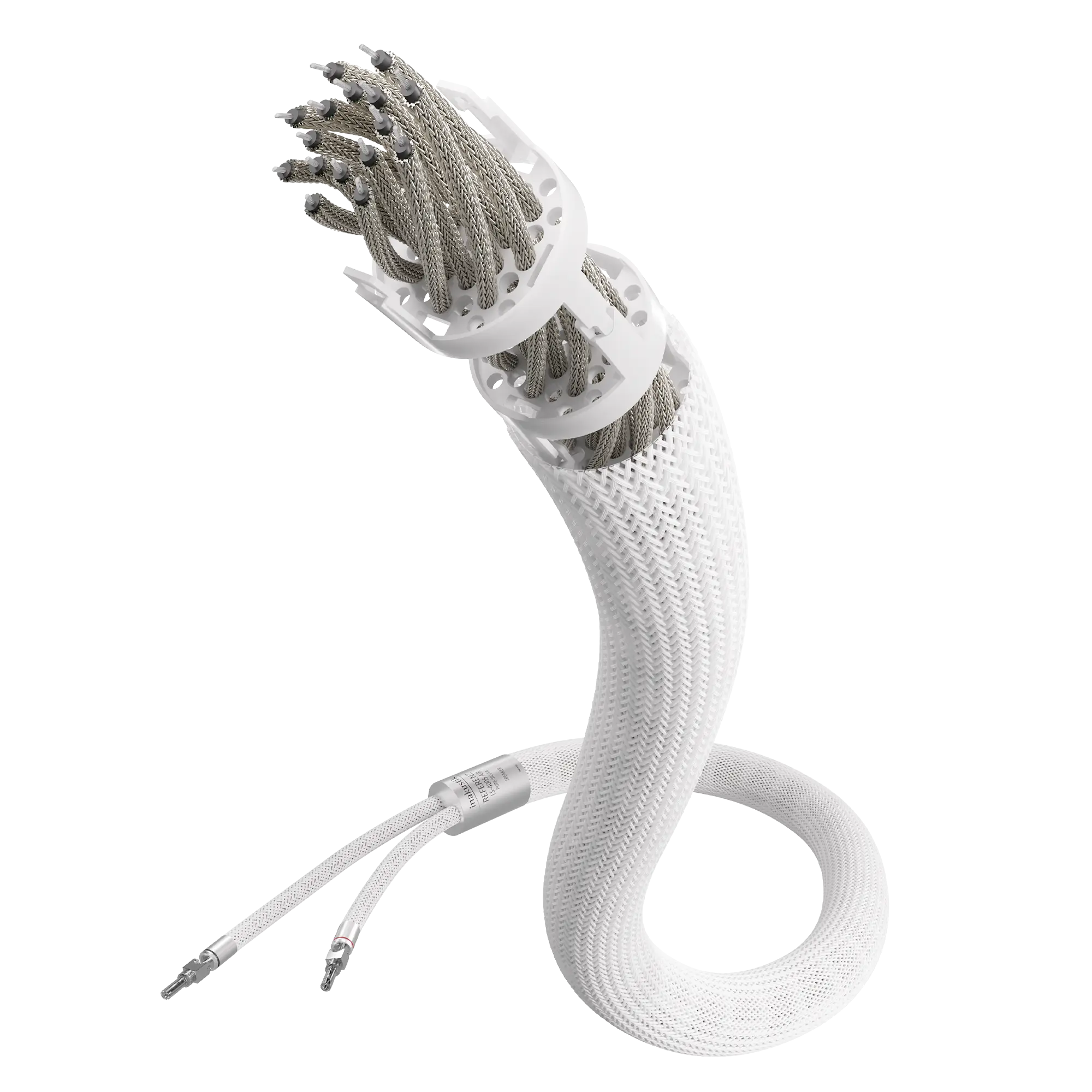

| Connector: | Banana Cable lug |

| Connector highlight: | BFA Banana 360° Spring-loaded contact fork Spade lug 360° |

| Made in Germany: | Yes |

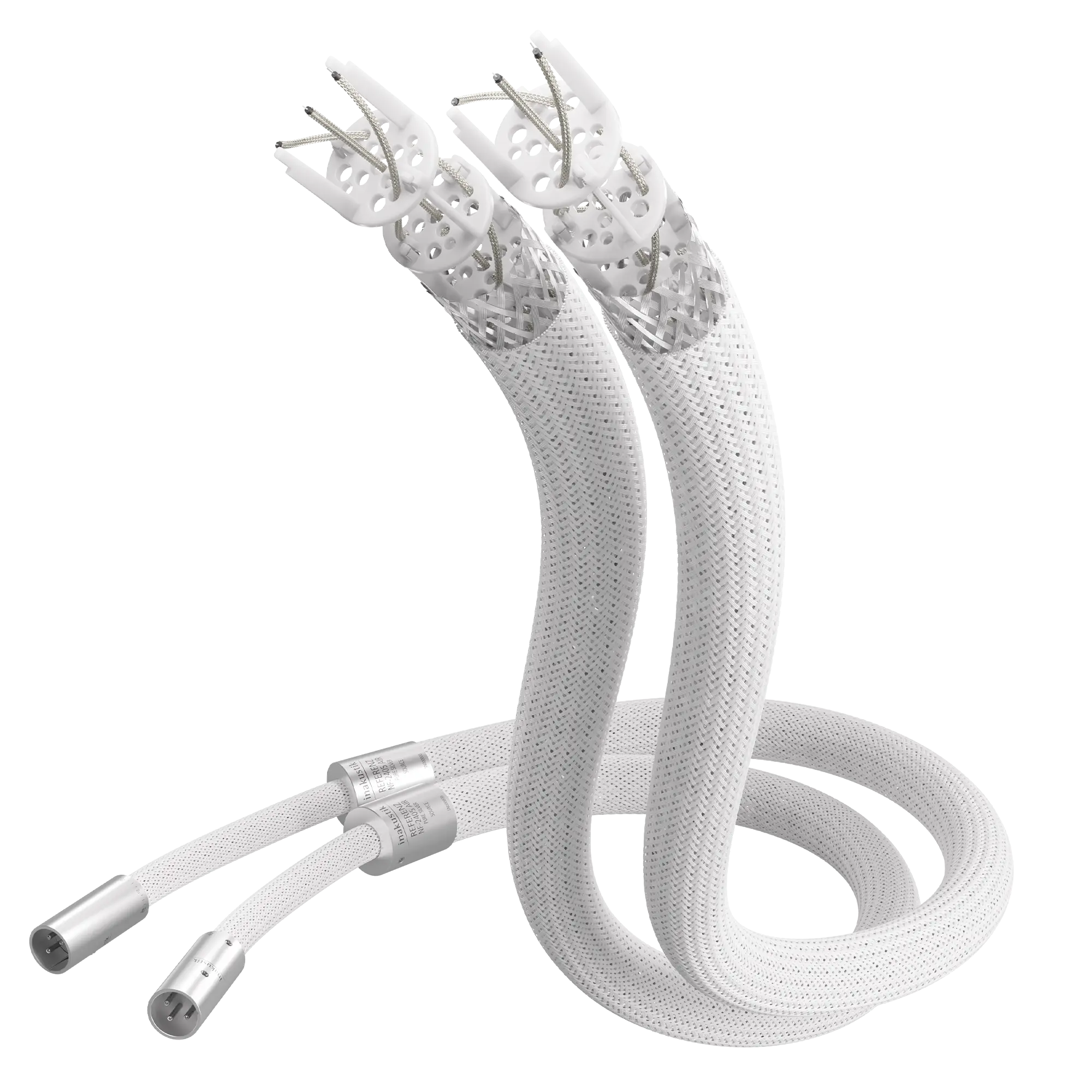

- Stereo set LS-4005 AIR speaker cable

- BFA banana & spade lug

- Allen key for changing the connectors

- Quality certificate

- Warranty card

- CD "Der Anlagenberater"

- Universal user manual

- Company profile

AIR technology is a milestone in our more than 46-year company history and is causing a sensation in the hi-fi industry worldwide. The approach itself sounds relatively banal: The physically induced losses must be minimized in order to transmit the original music signal as authentically and neutrally as possible. And, thanks to the AIR technology, loss-free transmission is closer than ever before. It leads to a significantly better reproduction, which is not only subjectively audible, but also objectively measurable.

The insulation (or dielectric) of the AIR cables is practically perfect thanks to the air insulation, and hardly affects the sound at all. The structure, dimensions and arrangement of the conductors are optimized, and approach the limits of what is physically possible. Adding another highlight to this perfect audiophile foundation, we then focused on the conductor material of the cables. Copper in the appropriate purity is already a very good conductor. A superconductor, where electrical resistance is zero, would be perfect, of course.

Unfortunately, superconducting materials require temperatures of at least -70 degrees. Under realistic operating conditions, the best conducting material we have is currently silver. At 61.35 S/m (Siemens pro Meter), its conductivity is approximately six percent superior to that of copper. However, this precious metal is about 100 times more expensive.

Below you can learn more about the outstanding technical features of this cable, the innovations in the 5th generation and the physical principles used in the AIR technology.

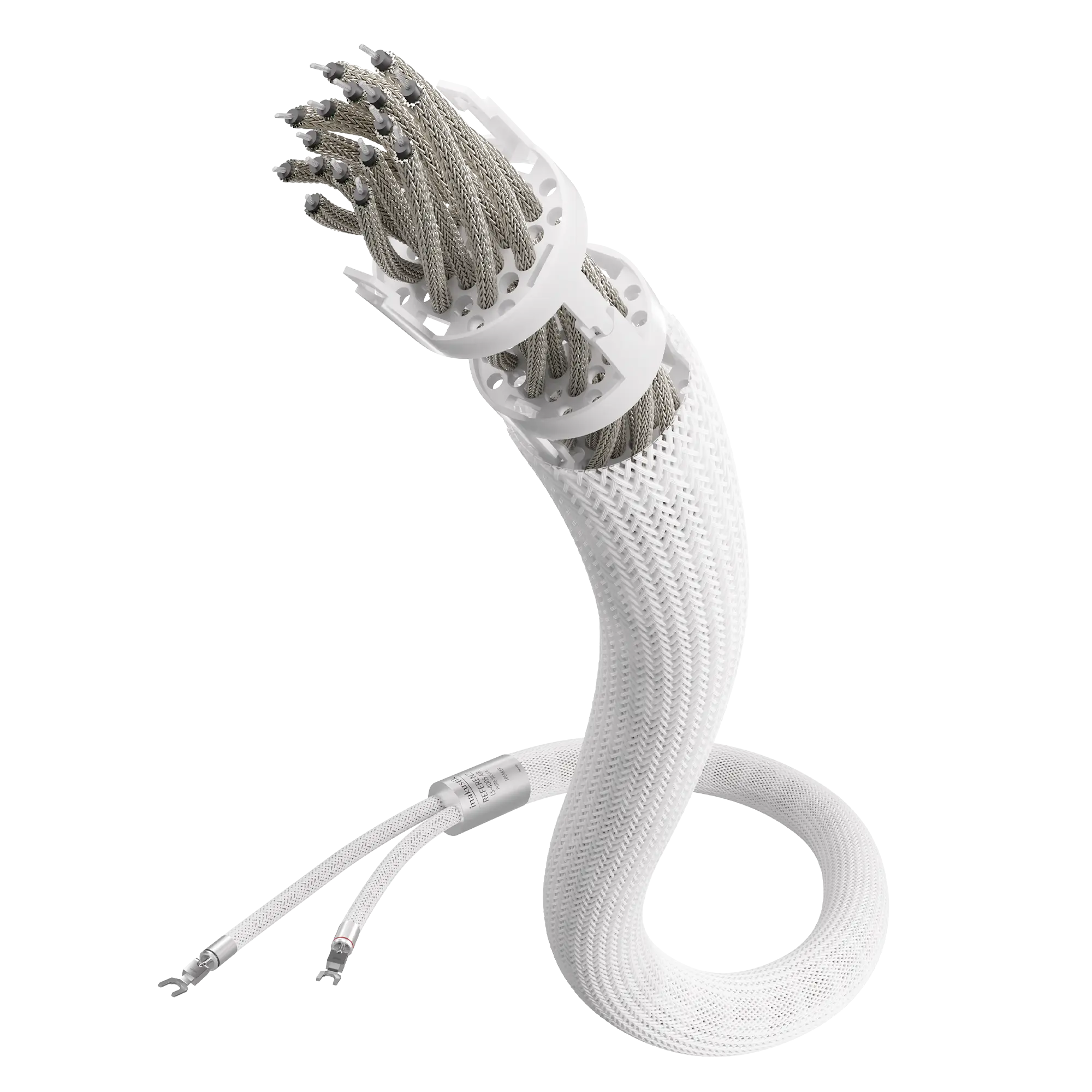

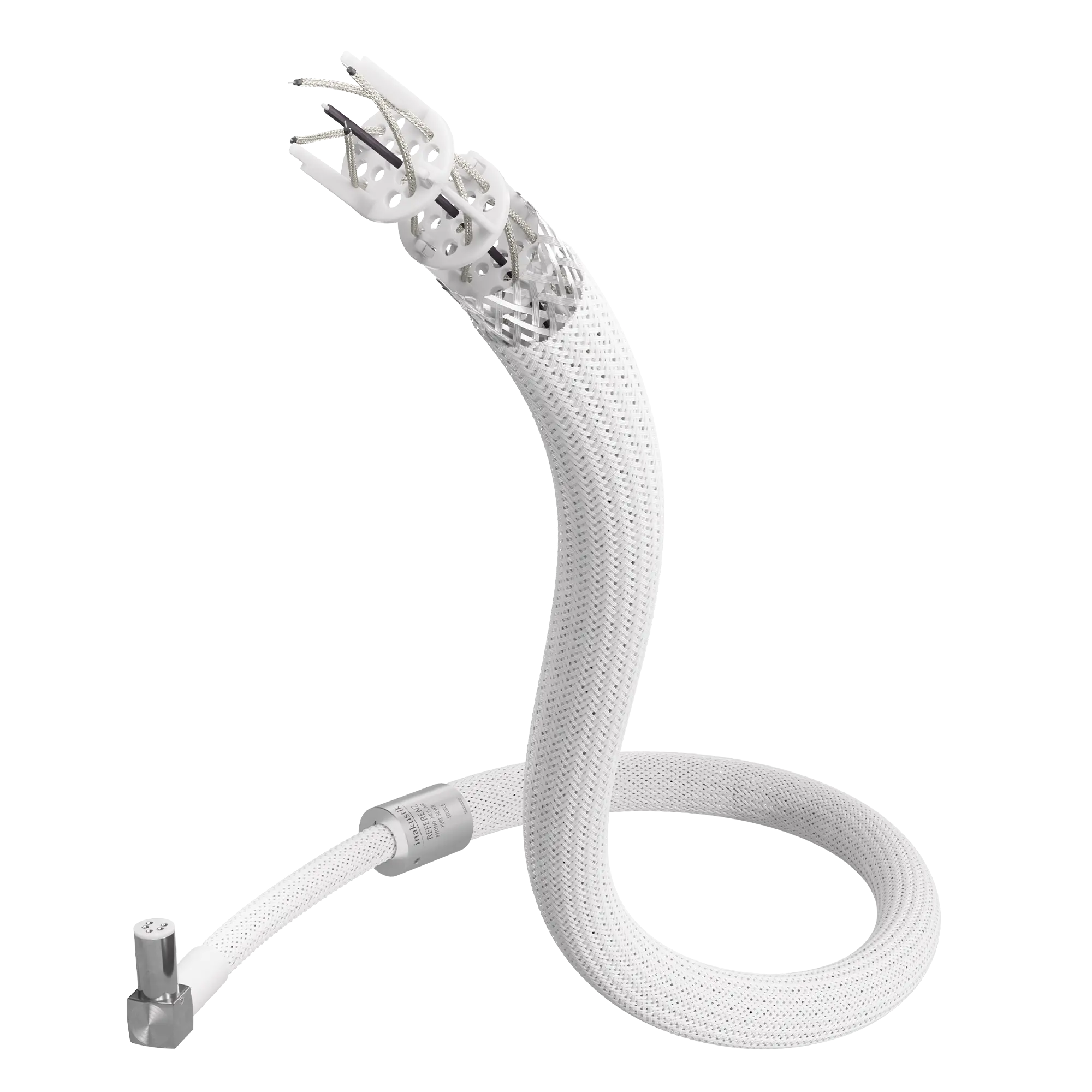

Click here and discover the exciting detailsThe LS-4005 AIR high-end speaker cable offers audiophile enthusiasts a unique sound experience. In the new Referenz LS-4005 AIR loudspeaker cable, we have taken the outstanding properties of its predecessor, the LS-4004 AIR, and developed them even further. The point-to-point Air Helix design now enables the AIR Helix architecture to be used from plug to plug and not just between the sleeves. The 360° BFA bananas and spade lugs are a further innovation, developed in-house for easy and convenient connection to the terminals. These and other technical refinements turn the already exceptional AIR cables into true masterpieces.

Below you can learn more about the outstanding technical features of this cable, the innovations in the 5th generation and the physical principles used in the AIR technology.

AIR technology is a milestone in our more than 46-year company history and is causing a sensation in the hi-fi industry worldwide. The approach itself sounds relatively banal: The physically induced losses must be minimized in order to transmit the original music signal as authentically and neutrally as possible. And, thanks to the AIR technology, loss-free transmission is closer than ever before. It leads to a significantly better reproduction, which is not only subjectively audible, but also objectively measurable.

The insulation (or dielectric) of the AIR cables is practically perfect thanks to the air insulation, and hardly affects the sound at all. The structure, dimensions and arrangement of the conductors are optimized, and approach the limits of what is physically possible. Adding another highlight to this perfect audiophile foundation, we then focused on the conductor material of the cables. Copper in the appropriate purity is already a very good conductor. A superconductor, where electrical resistance is zero, would be perfect, of course.

Unfortunately, superconducting materials require temperatures of at least -70 degrees. Under realistic operating conditions, the best conducting material we have is currently silver. At 61.35 S/m (Siemens pro Meter), its conductivity is approximately six percent superior to that of copper. However, this precious metal is about 100 times more expensive.

Below you can learn more about the outstanding technical features of this cable, the innovations in the 5th generation and the physical principles used in the AIR technology.

Click here and discover the exciting detailsExperts have already been impressed by the LS-1204 AIR (copper). This is how AUDIO summed it up: "A stroke of genius that shows competitors how it should be done – in terms of sound, too. This was wonderfully dynamic, with the most fabulous drive reaching the speaker cones. Admittedly, the price is not low, but the acoustic yield is truly world class. What's more, everything was made by hand. You can feel the love for the product."

With the LS-1205 AIR Pure Silver, the currently most filigree model in AIR technology is now also available as a pure silver cable. The structure, dimensions and conductor arrangement of this cable correspond to the copper version of the LS-1205 AIR. As with the LS-4005 AIR Pure Silver and LS-2405 AIR Pure Silver, the conductors have been optimized. Pure silver is used as the conductor material for the LS-1205 AIR Pure Silver too. Under realistic conditions, silver is currently the most conductive material. At 61.35 S/m (Siemens pro Meter), its conductivity is approximately six percent superior to that of copper. The electrons move 1.5 times faster than in a copper conductor!

€35,499.00*

€7,799.00*

€21,499.00*

€12,499.00*

Login

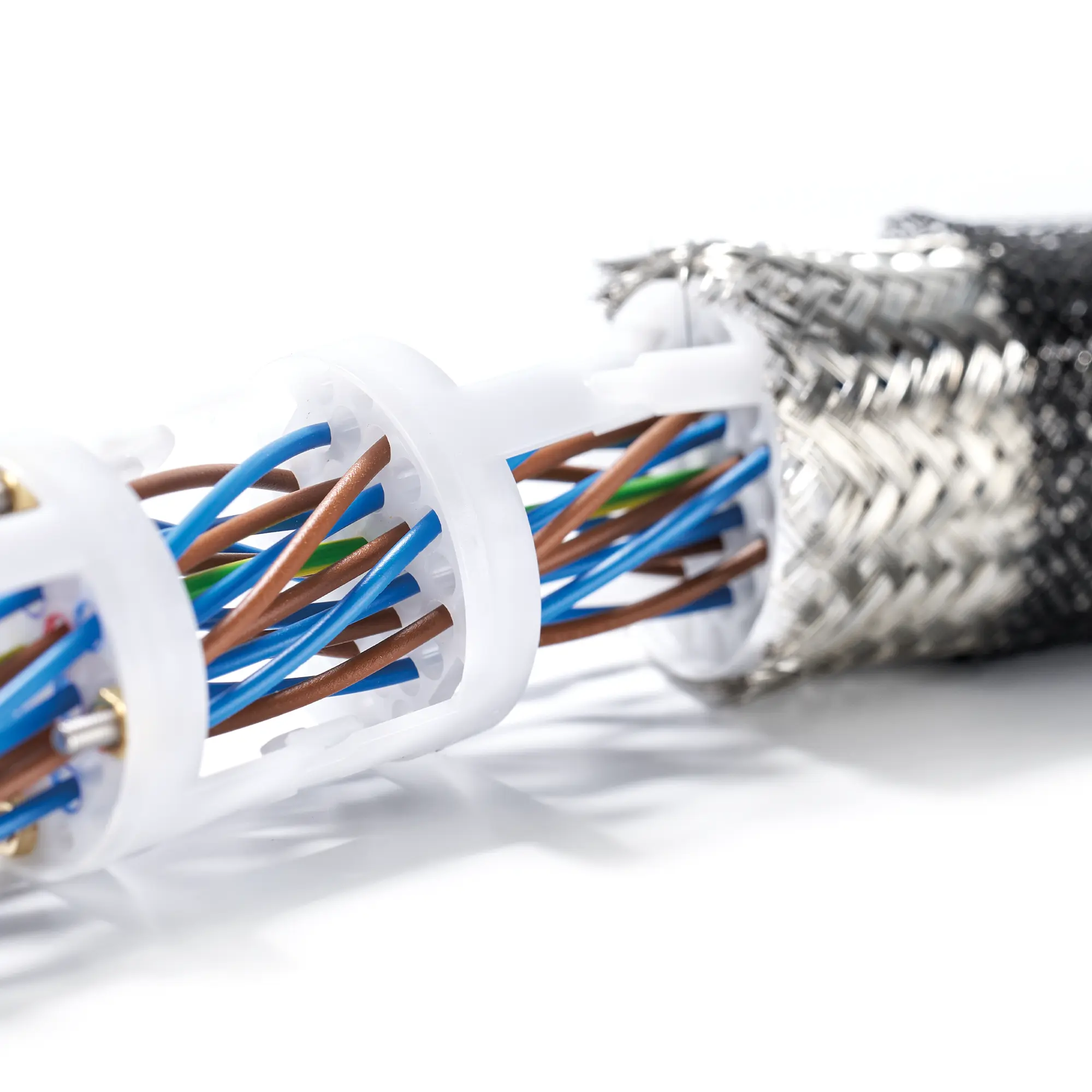

Thanks to the Air Helix design, the conductors run freely suspended through the length of the cable.

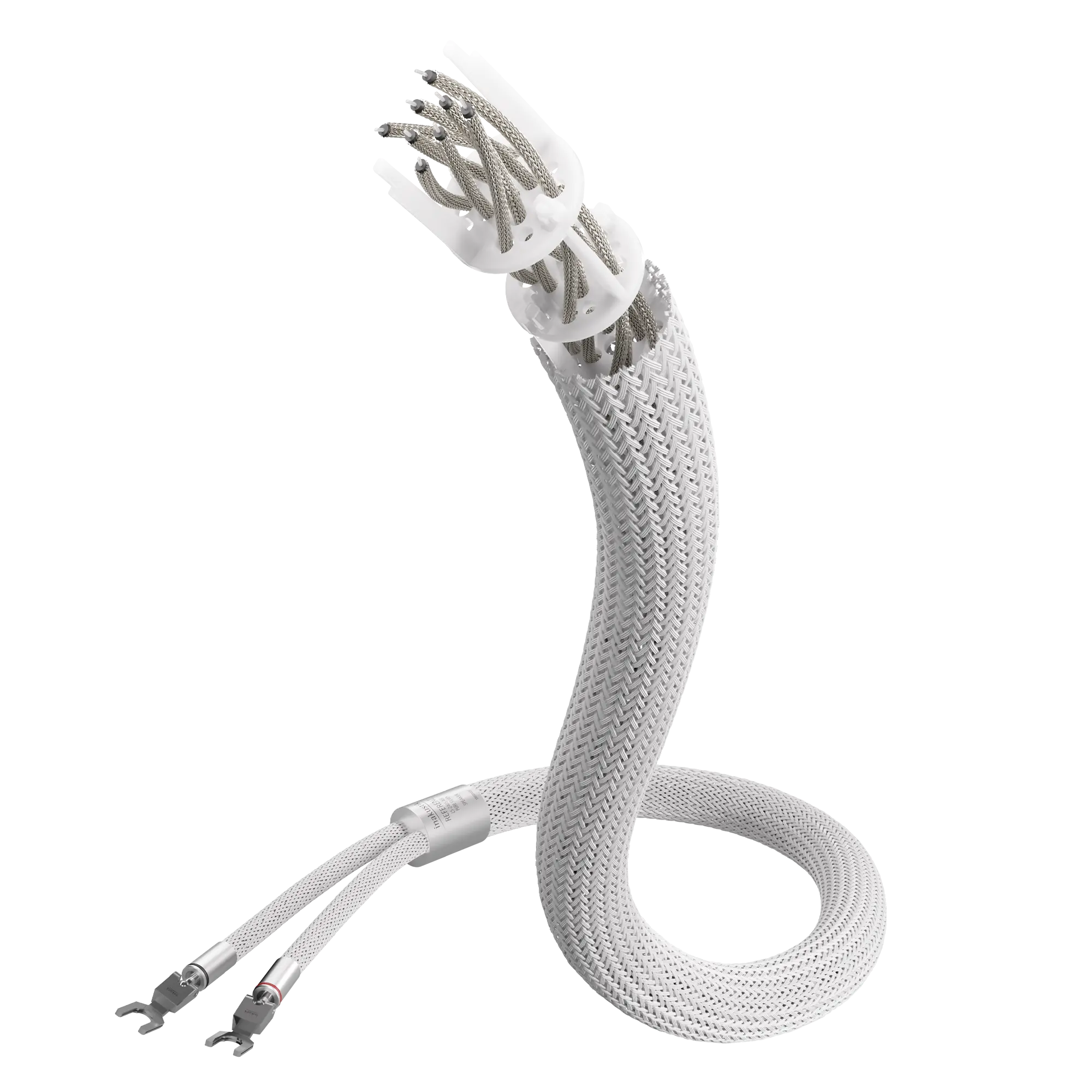

The Air Helix architecture permits signal conductors to be insulated to practically 100% by air. Special clips were developed to provide the supporting framework. Positioned at defined intervals inside the cables, these clips keep the helically-arranged conductors apart. Cable flexibility is assured by means of two struts that ensure the clips remain together but also at a precise distance from each other. This architecture is unique, bringing low capacitance and minimum dielectric losses – a true milestone in the search for open and unadulterated sound.

Our physical approach: Minimize losses for true-to-original playback.

Our Referenz AIR cables transport audio signals between source, amplifier and speaker in an authentic way and with a minimum of loss. You can enjoy music that precisely expresses the emotions of the artists at the time of recording – sensual, subtle, light-hearted or orchestral right through to full-blooded and rocking. Vocals and instruments are delivered in unadulterated form. Everything remains vibrant and full of emotive energy. Favorite tracks and pieces continue to trigger strong feelings even when you’ve heard them a hundred time over.

To the point

AIR Helix

The Air Helix architecture enables the signal conductors to run freely suspended through the length of the cable and permits signal conductors to be insulated to practically 100% by air.

The dielectric

Using air as a dielectric lowers capacitance to a minimum. In comparison with other insulators, using air as a dielectric leads to no increase in capacitance and creates no dielectric losses.

Multicore structure

By cleverly arranging the conductors in the multiply nested multicore structures, overlapping magnetic field areas are created that significantly reduce inductance.

The conductors

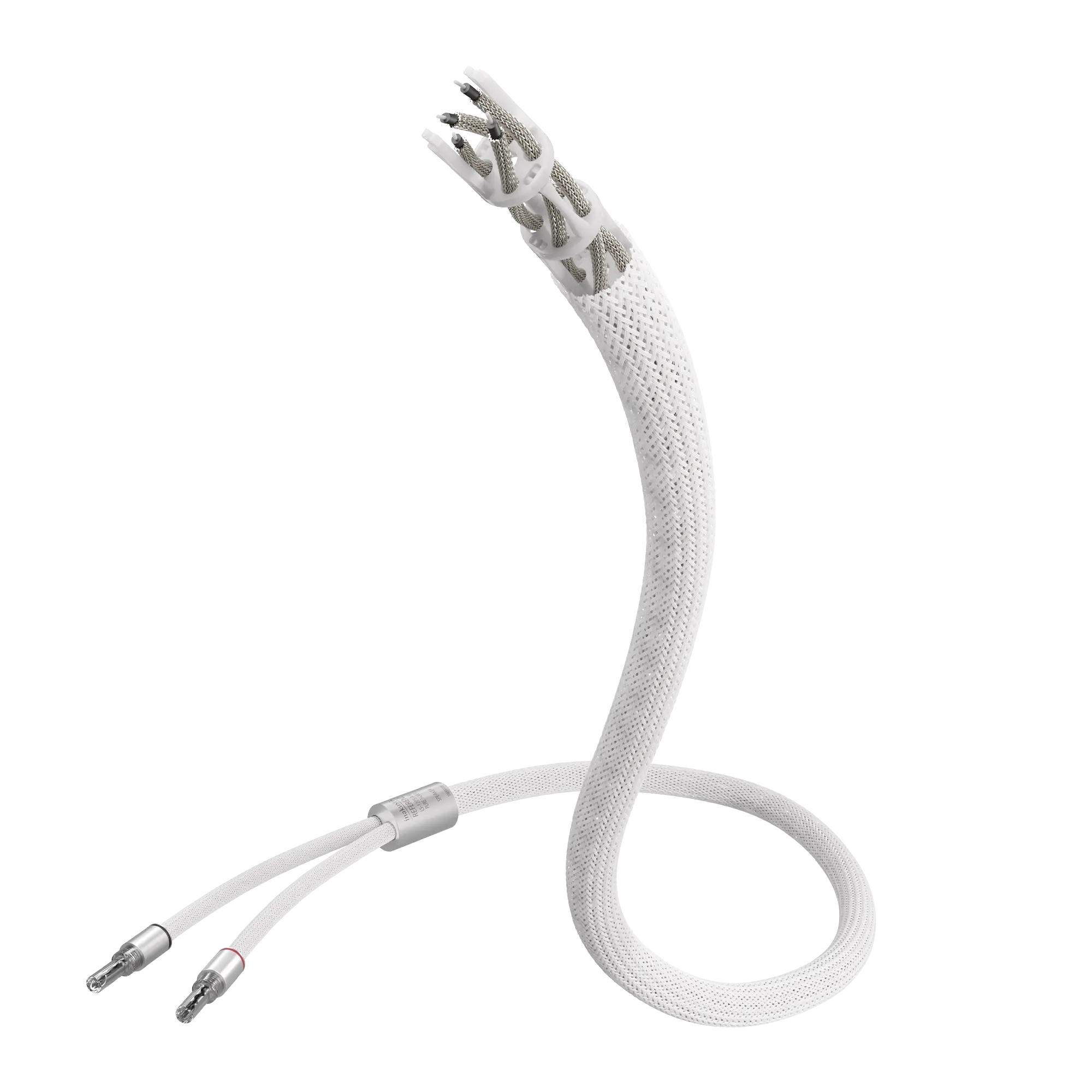

The Cross Link Super Speed waveguide avoids so-called skin effects and delivers a balanced sound, even with complex music passages and high volume levels.

Pressure-grouted contacts

The connectors are pressed directly into the conductor material of the cable using a special tool with a force of 1.5 tonnes. Contact resistance and other negative solder effects are avoided.

Point-to-point Air Helix for end-to-end connections

A new feature in the 5th generation of in-akustik’s Air Helix architecture is the point-to-point connection. Specially designed transitions are available for each type of cable and connector. Across the complete length of the cable – point-to-point AIR Helix. It may sound trivial at first, but the results are impressive. Sound signals are transported with minimized losses, right through to the final centimeters. The sound is more detailed and dynamic than even before.

The conductor structure

The Cross Link Super Speed waveguide avoids skin effects caused by eddy currents in the conductor. Thanks to the braided structure, the waveguide is able to precisely transport even extreme current peaks. A lacquer coating around each wire prevents eddy currents within the conductor and protects against oxidation. All this results in a conductor that delivers a balanced sound consisting of vibrant and never overemphasized timbres, even in complex musical passages and at high volume levels.

Pure silver conductors

Pure silver is regarded as the best conductor, delivering more detail across all frequency ranges. The charismatic sound of pure silver is primarily due to its high drift speed. Pure silver cables shouldn’t be confused with silver-plated cables. Silver-plated cables are said to lend a metallic and aggressive character to the sound, something pure silver cables never do.

The multicore structure

Inductance is critical to the capacitance of a loudspeaker cable, By cleverly arranging the conductors in the multiply nested multicore structures, overlapping magnetic field areas are created that significantly reduce inductance. This allows the entire frequency spectrum, including high frequencies and dynamic impulse sequences, to be transported in an unimpeded way and with no delays. The music seems more exquisitely detailed, and the sound gains in fine dynamism. All details are kept distinct yet harmonious at the same time.

Cable manufacturing unit

The beating heart of in-akustik is our manufactory. This is where our success story is rooted – permeated by a congenial working atmosphere, a love of music and a passion for detail. At in-akustik, we believe musical enjoyment stems from a listening experience that remains as close as possible to the original recording and the artist’s interpretation of the piece. That’s why we boast a committed workforce that combines curiosity with a keen sense of precision. With a fascination for music and things that are really special – like the development of our complex AIR cables.

Handmade

Each cable is handcrafted with the utmost care. Our extensive know-how and the qualifications of our team enable us to manufacture the complex cables in a customized manner. Apart from the finest of materials, our most important resource is the manual dexterity of our cable assemblers. In assembling our outstanding cables, they demonstrate meticulousness, composure and dedication.

Rigorous quality control

We manufacture in accordance with the highest standards. Rigorous quality control is carried out before, during and subsequent to assembly. We verify the tolerances of ever individual component. At every stage of manufacturing, we check the configuration and electrics for short-circuits. We also conduct functional and mechanical testing. No product leaves our manufacturing unit without a final quality check.

Did you know...

...that our LS-4005 AIR Pure Silver (2 x 3 m) is made up of 354 individual components? The pure silver wire used is 4,601 m long, and the PE monofilament is 1,723 m long. Containing 1,904 drill holes, the Air Helix design of this cable type demands great dexterity on the part of the assemblers when they’re threading through the conductors.

BFA Banana & Spade 360°

Movement across three axes make the 360-degree BFA and spade connectors really easy to connect and disconnect. Difficult set-up operations that put a strain on both cables and devices are a thing of the past. The connectors can easily be attached to terminals from a wide range of manufacturers. No awkward bending is necessary, avoiding damage to surfaces and potential contact resistance. Set-up is fast and problem-free. The attractively designed connectors are the perfect complement to the outstanding sound.

Rhodium-coated

The best cable requires optimum connection technology. We use tellurium copper, a harder metal alloy that maintains the high conductivity value. Much superior to that of brass connectors. The rhodium coating ensures long-lasting contact and corrosion resistance. The stable conductivity is even maintained with frequent conversions. This is better than gold contacts, which wear out quicker.

Pressed contacts (1.5 tonnes)

The contact elements of the connectors are pressed directly into the conductor material using a special tool with a force of 1.5 tonnes. This creates a stable and reliable connection without the use of solder or ferrules. Transition resistances and negative effects are avoided to ensure optimum signal transmission.

Test listening at home now

Are you curious to know whether the AIR cables keep the finest details precisely and harmoniously on your system? Test our AIR cables or an audio component from our partner companies Primare and Audiovector in your home for 14 days with no strings attached!

Book a listening sessionOr directly to the nearest dealer!

We work with a network of authorized dealers and distributors throughout the world. Arrange a listening appointment now.

Find a in-akustik partner