€578.99*

The LS-104 is an excellent entry-level model to the Micro AIR series. It already stands out clearly from standard cables and demonstrates the acoustic potential of this technology. Sensitive amplifiers in particular harmonize excellently with this cable. The Referenz LS-104 Micro AIR provides an open and relaxed sound. It is also available with BFA bananas or spade lugs and as an Easy Plug version.

| Application: | High-end speaker cable |

|---|---|

| Cable diameter: | 8.5 mm |

| Conductor cross-section: | 2 x 2.62 mm² |

| Conductor design: | Concentric copper |

| Conductor material: | High-purity OFC copper |

| Conformity: | CE, REACH, RoHS |

| Connection type: | SW |

| Connector housing: | Solid metal |

| Contact enhancement: | Rhodium-coated |

| Contact material: | Beryllium Copper (BFA Banana), Brass (cable lug) |

| Customized assembly: | On request |

| Design: | Twisted pair |

| Dielectric: | Air chambers |

| Length: | 2 x 3 m |

| Product group: | Loudspeaker cables |

| Product category: | Exzellenz speaker cables |

| Quality: | Referenz |

| Technology: | Micro AIR Twisted pair |

| Connector: | Banana Cable lug Easy Plug |

| Connector highlight: | Spring-loaded contact fork |

| Made in Germany: | Yes |

- 1 x stereo set Referenz LS-104 Micro AIR

- Quality certificate

The LS-104 is an excellent entry-level model to the Micro AIR series. It already stands out clearly from standard cables and demonstrates the acoustic potential of this technology. Sensitive amplifiers in particular harmonize excellently with this cable. The Referenz LS-104 Micro AIR provides an open and relaxed sound. It is also available with BFA bananas or spade lugs and as an Easy Plug version.

The LS-404 Micro AIR is a further installment in the success story of the Micro AIR technology: As with the already legendary AIR Helix cables, air is also a central component of the insulation concept in the Referenz Micro AIR technology. Due to the low speaker impedances, however, low line resistances and a low inductance are also very important for speaker cables. For this reason, the Referenz LS-404 Micro AIR uses a total of 8 concentric copper conductors in addition to the air dielectric. Thanks to this multicore architecture, the magnetic fields of the positive and negative conductors overlap and neutralize each other. This significantly reduces the inductance of the cable, which guarantees unaltered transmission of the audio signal over a broad frequency spectrum. Due to our approach, the LS-404 has an extremely balanced sound character with precise timing, on top of a solidly controlled foundation. This cable is primarily designed for full-size floorstanding loudspeakers. The impression sound makes on the listener is always subjective, of course, and depends in no small part on the overall constellation of a hi-fi system. In the end, the decisive factor is your own personal listening impression.

Like the flagship model, the LS-204 is also based on Micro Air technology. The difference lies in the multicore architecture. Compared to the XL version, the LS-204 has four instead of six Concentric Copper conductors. This cable boasts an agile character and was primarily developed for slim floorstanding speakers with smaller bass drivers. The Referenz LS-204 Micro AIR is available as a single-wire version with BFA bananas or spade lugs, or as an Easy Plug version.

The new Referenz Micro AIR series is a further installment in the success story of the Micro AIR technology: As with the already legendary AIR Helix cables, air is also a central component of the insulation concept in the new Referenz Micro AIR technology. Due to the low speaker impedances, however, low line resistances and a low inductance are also very important for speaker cables. For this reason, the Referenz LS-204 XL Micro AIR uses a total of 6 concentric copper conductors in addition to the air dielectric. Thanks to this multicore architecture, the magnetic fields of the positive and negative conductors overlap and neutralize each other. This significantly reduces the inductance of the cable, which guarantees unaltered transmission of the audio signal over a broad frequency spectrum. Due to our approach, the LS-204 XL has a balanced sound character with precise timing, on top of a solidly controlled foundation. This cable is primarily designed for full-size floorstanding speakers. Sound, of course, is always subjective and depends not least on the overall constellation of a hi-fi system. In the end, the decisive factor is your own personal listening impression.

€578.99*

€998.99*

€749.00*

€899.00*

Login

Micro AIR technology

We are not able to switch off the laws of nature, so the best we can do is use them as ingeniously as possible. Due to the laws of nature, every cable exerts so-called parasitic effects. These include capacitance – the capacity to store energy like a battery and release it again with a time delay. This effect has a considerable impact on the transmission of audio signals and is therefore unwelcome. Capacitance is a physical property, and its value depends on a number of different factors, one of the most important of which is the insulation material used, also known as the “dielectric”. The dielectric material can considerably increase the capacitance of the cable. Because air doesn’t do this, it’s ideal for insulation purposes. One of the insulation elements in the Micro AIR technology is a complex, diamond-shaped structure. The tiny chambers created by this structure increase the distance between the conductors and raise the air content of the insulation. This method reduces troublesome capacitance effects and optimizes the cable’s transmission characteristics for the sensitive audio signals it needs to transport.

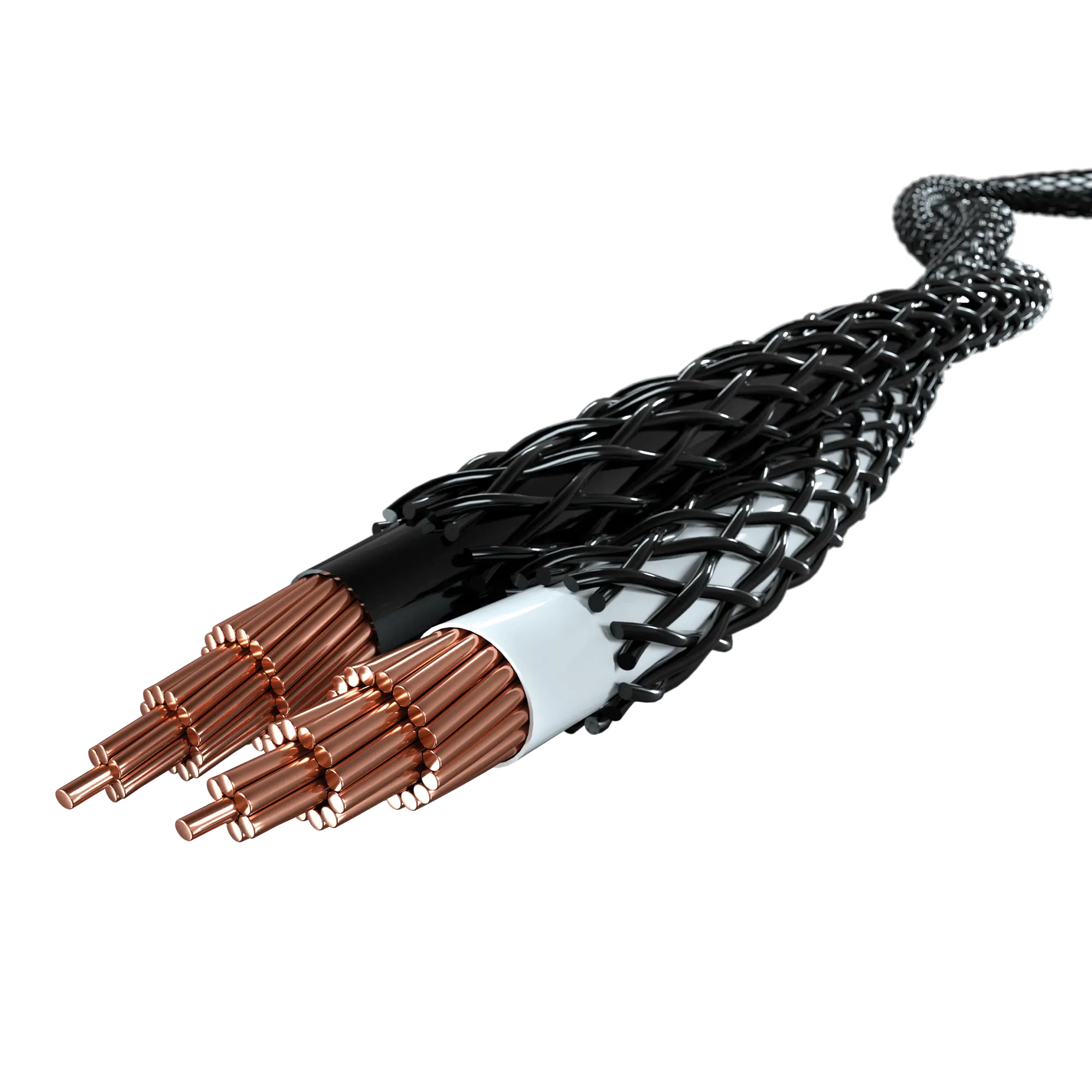

Concentric copper

Unlike the sometimes chaotic arrangement of individual wires in conventional conductor designs, concentric copper conductors are arranged in a precisely defined multi-layer pattern. This design reduces irregular contact points between the wires, which harmonizes the signal flow and minimizes runtime differences. Impulses can be reproduced with pinpoint accuracy and the spatial information of the music is retained. A thin layer of polyethylene protects the high-purity copper from oxygen and thus from oxidation.

Copper is the best electrical conductor after silver under normal conditions. Compared to cheap CCA (Copper Coated Aluminum) in particular, copper has a significantly better conductivity and is also mechanically more resilient. The conductors of the Micro AIR cables are made of high-purity OFC (Oxygen Free Copper).

Electrostatics and capacitance

It’s something we’re all familiar with: when you take off a sweater with a high synthetic content you hear a crackling sound. The reason for this is that the integrated plastic material stores electrical energy, and then discharges it again. The same thing happens in the dielectric material of a cable. It “absorbs” electrical energy like a sponge and then releases it again. In the case of an audio cable, however, this electrical energy is part of the audio signal.

This problematic storage capacity of a cable is referred to as its “capacitance”. While capacitors intended to store energy should have a correspondingly high capacitance, the capacitance of a cable should be as low as possible. If this is not the case, it can have a serious detrimental effect on the transmission characteristics and also lead to interactions with connected electronic devices. The ideal solution is therefore air insulation such as that implemented with the Micro AIR (and previous AIR technology), reducing the capacitance to an absolute minimum.

Cables should not make any sound

The Referenz AIR series cables have already caused something of a sensation in the world of high-end connections. And we have used the very same principles of physics to develop our Referenz Micro AIR series. As the name suggests, air as insulation also plays a key role with these high end connections due to the excellent dielectric properties.

Cables in general don’t make any sound; they have a filtering effect and interact with the devices. We believe audio connections should be as unobtrusive as possible and cause no sound coloration. These would perhaps be astonishing to hear the first time, but they actually distort the original, and eventually are annoying. The trick is to adapt the physical filter effect through the architecture and choice of materials so that losses and interactions are reduced to a minimum. This was our goal when developing the Referenz Micro Air series – and we believe we have achieved our goal once again.

Made in Germany

Just like the AIR Helix cables, the Referenz high-end cables with Micro AIR technology are also manufactured in our own factory in Germany. Along with the complex, manual assembly of the cables, this of course also includes the corresponding quality control. Every cable is put through its paces after production. Both functional tests and mechanical tests are carried out. And of course we also check the live performance as part of product development – for maximum precision and low-loss signal transmission.

Cable manufacturing unit

The beating heart of in-akustik is our manufactory. This is where our success story is rooted – permeated by a congenial working atmosphere, a love of music and a passion for detail. At in-akustik, we believe musical enjoyment stems from a listening experience that remains as close as possible to the original recording and the artist’s interpretation of the piece. That’s why we boast a committed workforce that combines curiosity with a keen sense of precision. With a fascination for music and things that are really special – like the development of our complex AIR cables.